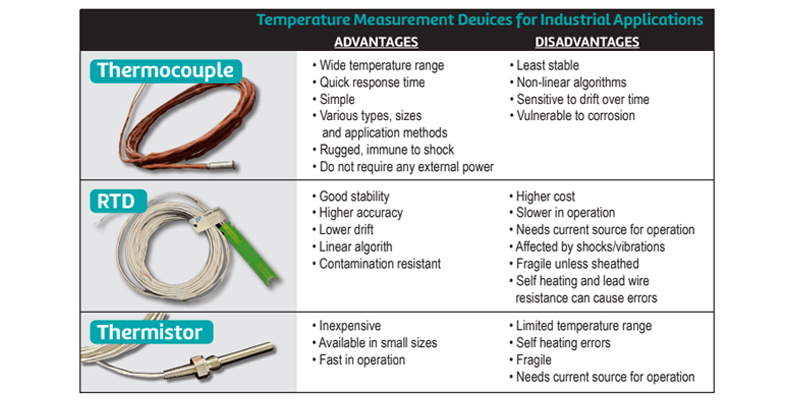

Understanding the types of sensors, their application, the environment where they operate, and the parameters they measure are key elements of effective temperature measurement

Choosing the best industrial temperature sensor is no easy task. It is a highly sensitive sort of application that necessitates not just experience and knowledge of thermal dynamics, but also of the materials used and how temperature sensing devices will react in the environment where they monitor the temperature.

With this in mind, we’d want to utilize straightforward language to educate you on how our temperature sensor solutions can better meet your demands. After all, AAVAD is a company founded on the success of countless clients and OEMs who rely on our expertise in industrial temperature measuring. Precision and accuracy are ensured by our custom solutions and temperature measurement instruments for industrial applications.

Three defined devices for sensing temperature measurement for industrial applications are Resistance Temperature Detectors (RTDs), Thermocouples, and Thermistors. Each has a different range of applications and thus serves a different industrial objective.

RTD Sensors – A resistance temperature detector works by monitoring how a metal resistor reacts to temperature changes—an activity that may be monitored to yield a temperature measurement. Understanding the link between that metal, such as platinum, nickel, or copper, enables for the measurement of its resistance and the related linear temperature reading. An RTD has a temperature range that commonly ranges from -200°C to 650°C. Given their complexity and ability to measure a larger temperature range, RTDs tend to be more expensive to produce.

Thermocouples – Thermocouples are temperature measurement devices that utilise the Peltier Effect, which is the generation of electrical voltage in response to heat or cold. These devices employ two distinct metals to generate such an electrical reaction, and depending on the metal type, they can measure a specified range of hot and cold temperatures. As a result of its design, thermocouples are more effective than other types of thermometers at measuring temperature at a faster rate. A thermocouple has a temperature range that commonly ranges from 200°C to 1,750°C. When compared to RTDs, the cost of creating a thermocouple is comparatively inexpensive.

Thermistor – A thermistor is a sort of resistor thermometer that is used to regulate temperature, either as a Negative Temperature Coefficient (NTC) or a Positive Temperature Coefficient (PTC). Despite being limited to lower temperature ranges, thermistors are extremely good at monitoring very minute changes in the temperature of a device or industrial environment. Calibrating an NTC or PTC thermistor enables reliable measurement with uses that extend beyond other types of industrial temperature sensors. A thermistor typically has a temperature range ranging from -100°C to 325°C. Furthermore, the cost of creating a thermistor is thought to be on the lower end of the cost curve.

Once again, the application of any of these industrial temperature sensors or a combination thereof is defined by the environment, the range of temperatures a client seeks to measure and other factors that can be best analyzed when you consult with one of AAVAD knowledgeable industrial thermometer experts. We have been producing these temperature measurement devices for several decades and our company has the expertise and insight to match the best device to an application.