Sodium silicate, commonly known as water glass, is a versatile chemical compound used in various industrial applications. Its unique properties, such as high heat resistance and adhesive strength, make it valuable in numerous manufacturing processes. To ensure efficient and controlled production of sodium silicate, accurate temperature monitoring is crucial. This blog explores the use of thermocouples in sodium silicate production and how they contribute to quality and process optimization.

Understanding Sodium Silicate Production

Sodium silicate is typically produced through the reaction of silica sand (SiO2) and sodium carbonate (Na2CO3) at high temperatures. This exothermic reaction requires precise temperature control to obtain the desired product properties. During the process, monitoring and maintaining the temperature levels are essential to ensure consistent product quality and avoid production issues.

Introduction to Thermocouples

A thermocouple is a temperature sensor that operates based on the principle of the Seebeck effect, where a voltage is generated across two dissimilar metals when subjected to a temperature gradient. It consists of two wires made of different materials, commonly known as the positive and negative wires. These wires are connected at one end, known as the sensing junction, and connected to a temperature indicator at the other end.

Role of Thermocouples in Sodium Silicate Production

Thermocouples play a crucial role in the sodium silicate production process by providing real-time temperature data. Here are some of their key functions:

- Temperature Monitoring: Thermocouples are inserted into the reaction vessel to measure the temperature accurately. Operators can observe and control the temperature fluctuations during the exothermic reaction, ensuring it stays within the optimal range.

- Process Optimization: By closely monitoring temperature changes during the reaction, manufacturers can identify potential inefficiencies or anomalies. This data can then be used to optimize the process parameters for better yield and quality.

- Safety: Sodium silicate production involves high temperatures and exothermic reactions. Thermocouples help prevent overheating or runaway reactions, reducing the risk of accidents in the production facility.

Choosing the Right Thermocouple

Selecting the appropriate type of thermocouple for sodium silicate production is essential to ensure accurate and reliable temperature measurements. Factors to consider include:

- Temperature Range: Ensure that the chosen thermocouple can withstand the high temperatures encountered during the reaction.

- Corrosion Resistance: Sodium silicate can be corrosive, so the thermocouple’s materials should be resistant to the chemical environment.

- Response Time: The thermocouple’s response time must be adequate to provide real-time temperature readings.

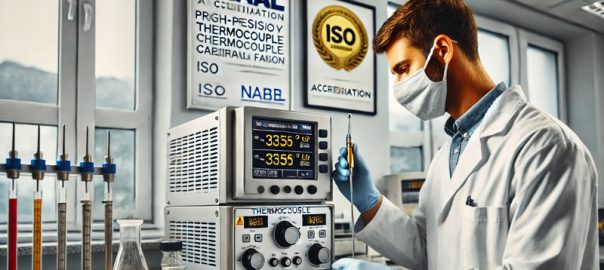

- Calibration: Regular calibration of the thermocouples is necessary to maintain measurement accuracy.

Maintenance and Calibration

To ensure the accuracy of temperature readings, regular maintenance and calibration of thermocouples are vital. Periodic checks and calibrations should be conducted to verify the sensors’ accuracy and make any necessary adjustments.

Benefits of Thermocouples in Sodium Silicate Production

- Accurate Temperature Measurement: Thermocouples offer high accuracy in temperature monitoring, allowing manufacturers to maintain the desired reaction temperature range. This precision ensures consistent product quality and minimizes the risk of producing off-spec material.

- Real-time Monitoring: Thermocouples provide real-time temperature data, enabling operators to respond promptly to any temperature fluctuations or deviations during the reaction. This capability helps prevent production delays and potential issues with the final product.

- Process Control and Optimization: The data collected by thermocouples can be used to optimize the production process. By analyzing temperature profiles and correlating them with reaction outcomes, manufacturers can make data-driven decisions to improve yield and reduce production costs.

- Non-intrusive Measurements: Some thermocouples are designed to be non-intrusive, allowing them to be mounted externally on the reactor vessel. This feature minimizes interference with the reaction while still providing accurate temperature readings.

Conclusion

Thermocouples play a critical role in sodium silicate production by providing precise and real-time temperature data. Their implementation ensures process optimization, quality control, and safety throughout the production process. By carefully choosing and maintaining thermocouples, manufacturers can enhance the efficiency of sodium silicate production and deliver high-quality products for various industrial applications.