Mineral-insulated cables are commonly used for thermocouples and RTD sensors because they offer excellent temperature stability, durability, and resistance to corrosion and environmental hazards. These cables consist of a metal sheath, usually made of stainless steel, and a mineral insulation material, typically magnesium oxide (MgO), which is packed around the sensor wires.

For thermocouples, the two wires of the thermocouple are inserted into the mineral insulation and welded to the sheath at the tip, forming a thermocouple junction. The sheath of the cable acts as a protective barrier and provides electrical insulation to the thermocouple wires. The mineral insulation material provides a stable environment for the thermocouple wires, allowing for accurate temperature measurement.

For RTD sensors, the resistance wire is inserted into the mineral insulation and is typically wound into a coil or a flat element. The sheath of the cable provides mechanical protection to the RTD wire and the mineral insulation provides thermal insulation and stability for accurate temperature measurement.

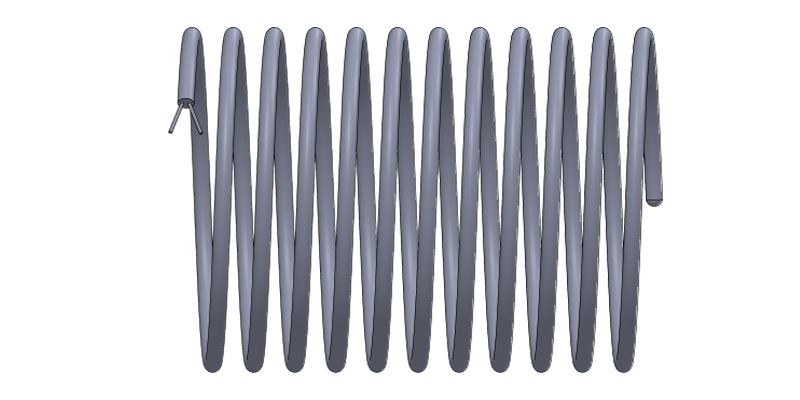

Mineral-insulated cables are available in various sizes and configurations to suit different applications. They can be bent and shaped to fit into tight spaces and can be used in high-temperature and harsh environments. The cables are also resistant to vibration, moisture, and chemical exposure, making them ideal for use in industrial and process applications.

Overall, mineral-insulated cables are a reliable and accurate solution for temperature measurement in a variety of applications, including those that require thermocouples or RTD sensors.