Introduction:

Brief overview of the importance of accurate flow measurement in Effluent Treatment Plants (ETPs).

Introduction to Electromagnetic Flow Meters (EMFs) and their unique capabilities.

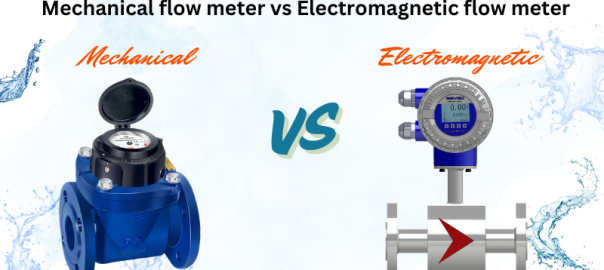

- Understanding Electromagnetic Flow Meters (EMFs):

Explanation of the principle of operation: induction of a magnetic field and measurement of induced voltage proportional to fluid velocity.

Comparison with other flow measurement technologies.

Advantages of EMFs: accuracy, reliability, versatility, and suitability for a wide range of fluid types and conditions. - Applications in Effluent Treatment Plants (ETPs):

Importance of flow measurement in ETPs for process control, regulatory compliance, and resource optimization.

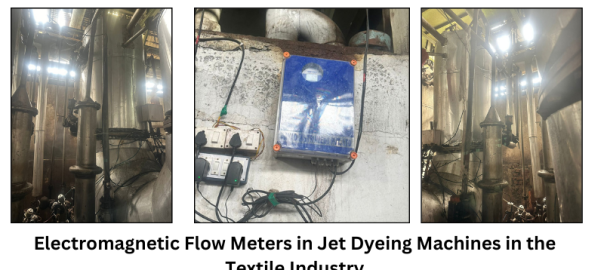

Specific challenges in ETPs and how EMFs address them (e.g., measuring corrosive or abrasive fluids, wide range of flow rates).

Case studies or examples demonstrating successful implementation of EMFs in ETPs. - Advantages of Electromagnetic Flow Meters in ETPs:

Accurate measurement of flow rates, even in challenging conditions.

Non-intrusive design minimizes pressure drop and maintenance requirements.

Compatibility with various pipe materials and sizes.

Ability to measure bidirectional flow.

Resistance to wear and corrosion. - Installation and Maintenance Considerations:

Best practices for EMF installation, including sensor placement, grounding, and calibration.

Routine maintenance procedures to ensure long-term performance and accuracy.

Integration with ETP control systems for real-time monitoring and data logging. - Future Trends and Innovations:

Emerging technologies and advancements in EMF design (e.g., digital signal processing, wireless communication).

Potential future applications and improvements in accuracy, reliability, and efficiency.

Conclusion:

Recap of the importance of Electromagnetic Flow Meters in optimizing the performance of Effluent Treatment Plants.

Encouragement for ETP operators and engineers to leverage EMF technology to enhance efficiency, compliance, and sustainability.