Swaged tip thermocouples are thermocouples designed for specific use in which the thermal detecting element area is decreased through swaging, resulting in a quicker response from the sensor. The tough construction of the thermocouple provides protection for the sensor from the effects of vibrations, extending its useful life and avoiding operation.

Swaging is a forging process that involves hammering and reshaping a workpiece with rotary dies. The swaging dies method uses over 500 blows per minute to obtain the required final, decreased diameter. The swaging procedure does not affect the structure’s ruggedness, but it does aid to boost tensile strength by strengthening the material’s grain structure. The thermocouple forging benefits from this procedure by being simple to construct and economical to manufacture. The procedure also increases resistance to being burned up.

Except for the bottom swage section where the sensor is positioned, these thermocouples have a wide diameter along their length to withstand extreme weather conditions. The sheath can be bent, twisted, and flattened to accommodate specific installations. The heat generated on the mineral-insulated swaged tip allows the sensor to be shaped into a specific shape without affecting performance.

Swaged Thermocouple Characteristics

- Because of the smaller thermal mass at the tip, the response is quick.

- Good insulating resistance along with good accuracy and stability during operation.

- High strength and suitability for difficult situations are provided by rugged construction.

- Cost Effective as compared to expendable thermocouples.

- The ceramic coated tip can be used to measure molten metal temperatures with great accuracy without destroying the sensor.

- Can be used with devices such as the digital pyrometer. a robust substitute for an expanded thermocouple.

Technical Specification

| Element | K, N, E, J, R, S, B. |

| Insulation material | Mineral Magnesium Oxide (MgO) |

| No. of sensors | Simplex |

| Hot junction | Grounded, Ungrounded |

| Sheath material | SS316, SS310 & Inconel 600 |

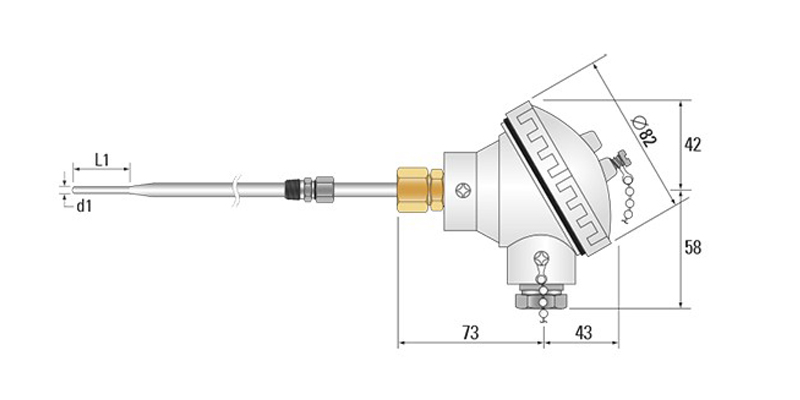

| Sheath diameter | 12.6, 10, 8, 6, etc. |

| Response Time | Less Than 10 sec. |

| Temperature Range | Depending on material |

| Process connection | Customizable according to applications. |

| Length of probe | Upto 2000mm. |

| Swaged Outer Diameter | Upto ~1mm for a length of up to 100mm. (Varies acc. to the sheath diameter). |

Swaged Thermocouple Applications

- Temperature measurements for molten metal and other materials.

- Process of smelting and casting.

- Engines for aircraft and automobiles.

- Ground equipment and gas turbines.

- Fluid flow temperature measurement under difficult circumstances.