Introduction:

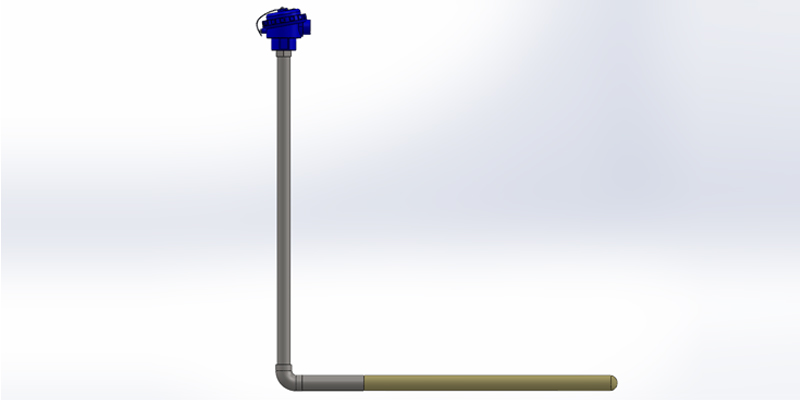

AAVAD Salt bath furnaces are widely used in various industries for processes such as heat treatment, metal melting, and chemical reactions. These furnaces require precise temperature monitoring to ensure optimal performance and product quality. One common type of temperature sensor used in salt bath furnace applications is the L-shaped Type K thermocouple. In this blog post, we will explore the features, benefits, and considerations of using L-shaped Type K thermocouples in salt bath furnace applications.

1. What is an L-Shaped Type K Thermocouple?

L-shaped Type K thermocouples are temperature sensors made from two dissimilar metals, typically nickel-chromium (NiCr) and nickel-aluminum (NiAl). They generate a voltage proportional to the temperature difference between their measurement junction and the reference junction. The L-shape design is characterized by a straight measurement leg and a 90-degree bend that serves as the reference junction.

2. Advantages of Using L-Shaped Type K Thermocouples:

2.1. Versatility: Type K thermocouples are compatible with a wide temperature range (-200°C to 1350°C), making them suitable for various applications, including salt bath furnaces.

2.2. Durability: L-shaped thermocouples are built to withstand harsh environments, such as the corrosive nature of salt baths, ensuring long-term reliability and performance.

2.3. Easy Installation: The L-shaped design allows for convenient installation and positioning within the furnace, enabling accurate temperature measurement at critical points.

2.4. Rapid Response: Type K thermocouples have a fast response time, providing real-time temperature data for immediate monitoring and control.

3. Considerations for Salt Bath Furnace Applications:

3.1. Salt Corrosion: Salt bath furnaces involve the use of corrosive molten salts, which can affect the lifespan of temperature sensors. Selecting L-shaped thermocouples with protective sheaths, such as ceramic or metal, can enhance their resistance to salt corrosion.

3.2. Temperature Uniformity: Salt baths need to maintain a uniform temperature throughout the process. Proper placement of L-shaped thermocouples at strategic locations within the furnace can help identify temperature variations and enable adjustments to achieve consistent results.

3.3. Calibration and Accuracy: Regular calibration of thermocouples is essential to ensure accurate temperature measurement. Working with a reputable calibration service provider or following industry standards is crucial for maintaining measurement accuracy.

4. Best Practices for L-Shaped Type K Thermocouple Usage:

4.1. Proper Grounding: Ensure proper grounding of the thermocouple wires to minimize electrical noise and interference.

4.2. Regular Maintenance: Perform routine inspections and maintenance to identify any signs of wear, damage, or drift in thermocouples. Replace or recalibrate them as necessary.

4.3. Backup Thermocouples: Consider using multiple thermocouples within the salt bath furnace to provide redundancy and cross-verification of temperature readings.

5. Types of Salt Bath Furnaces:

5.1. Open Tank Furnaces: These furnaces consist of an open tank or container filled with a molten salt bath. They are commonly used for processes like heat treatment of metal parts.

5.2. Sealed Quench Furnaces: Sealed quench furnaces have a sealed chamber where the workpieces are heated and then quenched in a controlled atmosphere or inert gas. This type of furnace is often used in the automotive industry for heat treating components like gears and shafts.

5.3. Continuous Salt Bath Furnaces: Continuous salt bath furnaces are designed for continuous processing of long and slender workpieces, such as wire or strip coils. They feature a conveyor system that carries the workpieces through the heated salt bath.

6. Benefits of Using L-Shaped Type K Thermocouples in Salt Bath Furnaces:

6.1. Resistance to Salt Contamination: L-shaped Type K thermocouples are less susceptible to salt contamination compared to other types of temperature sensors. The design of the reference junction, located away from direct contact with the salt bath, reduces the risk of sensor failure due to salt deposition.

6.2. Wide Range of Temperature Measurement: Type K thermocouples can accurately measure temperatures ranging from extremely low (-200°C) to high (1350°C). This versatility makes them suitable for a wide variety of salt bath furnace applications.

6.3. Compatibility with Standard Thermocouple Connectors: L-shaped Type K thermocouples typically use standard thermocouple connectors, such as miniature or standard size connectors. This compatibility allows for easy integration with existing temperature control systems and instrumentation.

7. Installation Considerations:

7.1. Location: Proper placement of L-shaped thermocouples is crucial for accurate temperature measurement. They should be positioned at critical points within the furnace where temperature differentials or variations are expected.

7.2. Immersion Depth: The measurement leg of the L-shaped thermocouple should be immersed adequately in the salt bath for accurate readings. However, care should be taken to avoid excessive immersion depth, which could lead to unnecessary sensor wear or damage.

7.3. Protection Sheaths: For enhanced durability and resistance to salt corrosion, L-shaped Type K thermocouples can be equipped with protective sheaths made of materials like ceramic or metal. The choice of sheath material should be based on the specific requirements of the salt bath process.

8. Maintenance and Troubleshooting:

8.1. Regular Calibration: To maintain accurate temperature measurements, L-shaped Type K thermocouples should be calibrated regularly. Calibration can help identify any drift or inaccuracies in the sensor’s output.

8.2. Sensor Replacement: Over time, thermocouples may become worn or damaged due to prolonged exposure to salt baths. It is important to monitor their condition and replace them promptly when necessary to avoid measurement errors or failures.

8.3. Troubleshooting: In the event of temperature inconsistencies or anomalies, troubleshooting steps should be taken to identify potential causes such as faulty wiring, grounding issues, or thermocouple damage. Prompt action can help minimize downtime and maintain process efficiency.

9. Temperature Control and Regulation:

9.1. PID Control: L-shaped Type K thermocouples provide real-time temperature feedback, enabling precise temperature control using a proportional-integral-derivative (PID) control algorithm. This control mechanism adjusts the furnace’s heat input based on the temperature readings, maintaining the desired setpoint and minimizing temperature fluctuations.

9.2. Over-Temperature Protection: In salt bath furnace applications, it is important to incorporate over-temperature protection systems to prevent excessive heat exposure or runaway temperatures. L-shaped thermocouples can be utilized as part of these safety systems, triggering alarms or shutting down the furnace if the temperature exceeds a predefined threshold.

10. Customization and Integration:

10.1. Length and Diameter Variations: L-shaped Type K thermocouples can be customized to suit specific furnace dimensions and requirements. Different lengths and diameters can be chosen to ensure proper fit and accurate temperature measurement at the desired locations within the furnace.

10.2. Integration with Data Acquisition Systems: To achieve advanced temperature monitoring and analysis, L-shaped thermocouples can be integrated with data acquisition systems. This allows for continuous data logging, visualization, and analysis of temperature trends, facilitating process optimization and quality control.

11. Safety Considerations:

11.1. Electrical Isolation: L-shaped Type K thermocouples generate a voltage signal that should be handled carefully to ensure electrical safety. Adequate electrical isolation measures, such as using insulated extension wires and connectors, should be implemented to prevent shocks or electrical hazards.

11.2. Personnel Protection: Salt bath furnaces operate at high temperatures and involve handling corrosive materials. Proper personal protective equipment (PPE), including heat-resistant gloves, goggles, and appropriate clothing, should be worn by personnel working in the vicinity of the furnace to ensure their safety.

12. Industry Applications:

12.1. Heat Treatment: Salt bath furnaces are commonly used in the heat treatment of metal components, such as annealing, quenching, and tempering. L-shaped Type K thermocouples provide accurate temperature measurement for precise control of these heat treatment processes.

12.2. Metal Melting: Salt bath furnaces can be employed for the melting and refining of metals and alloys. L-shaped thermocouples help monitor and maintain the desired melting temperatures, ensuring the quality and integrity of the melted material.

12.3. Chemical Reactions: Certain chemical reactions or processes require specific temperature control, which can be achieved using salt bath furnaces. L-shaped thermocouples play a crucial role in monitoring and controlling the temperatures during these chemical processes.

13. Calibration and Accuracy:

13.1. Traceability and Calibration Standards: To ensure accurate temperature measurement, it is important to follow calibration standards and guidelines. L-shaped Type K thermocouples should be calibrated using traceable references, such as certified calibration equipment, to maintain measurement accuracy.

13.2. Calibration Intervals: The frequency of calibration depends on the specific application and industry requirements. It is recommended to establish a regular calibration schedule to detect any drift or deviations in temperature readings and maintain measurement accuracy.

14. Variations in Salt Bath Composition:

14.1. Salt Composition Effects: Different salt bath compositions can impact the thermocouple’s performance and lifespan. Some salts may cause more corrosion or degradation than others. It is important to consider the specific salt composition in the furnace and select thermocouples with appropriate sheath materials or coatings to mitigate the effects of corrosive salts.

14.2. Contamination and Drift: Over time, the salt bath may become contaminated with impurities from the treated materials, which can affect temperature readings. Regular monitoring, maintenance, and cleaning of the salt bath are essential to minimize contamination and prevent drift in thermocouple readings.

15. Redundancy and Backup Systems:

15.1. Dual Thermocouple Configurations: To ensure continuous temperature monitoring and minimize downtime, using dual L-shaped thermocouples in critical furnace zones can provide redundancy. If one thermocouple fails or drifts, the other can serve as a backup, maintaining temperature measurement and control.

15.2. Alarms and Interlock Systems: Integrating temperature alarms and interlock systems with L-shaped thermocouples can provide an additional layer of safety. These systems can trigger warnings or automatically shut down the furnace in case of abnormal temperature deviations or failures, safeguarding the equipment and personnel.

16. Training and Expertise:

16.1. Proper Training: Operators and maintenance personnel should receive proper training on the installation, operation, maintenance, and troubleshooting of L-shaped Type K thermocouples in salt bath furnaces. This training helps ensure the correct handling, interpretation, and response to temperature data and potential issues that may arise.

16.2. Consultation with Experts: Consulting experts or thermocouple manufacturers with experience in salt bath furnace applications can provide valuable insights and guidance specific to your industry and furnace setup. They can assist in selecting the appropriate thermocouple configuration, sheath materials, and best practices for your specific application.

17. Emerging Technologies:

17.1. Wireless Temperature Monitoring: Advancements in wireless sensor technology have introduced the possibility of using wireless temperature monitoring systems in salt bath furnace applications. These systems can provide real-time temperature data without the need for physical wiring, offering flexibility and ease of installation.

17.2. IoT Integration: Integration with the Internet of Things (IoT) platforms allows for remote monitoring and control of salt bath furnaces. L-shaped thermocouples can be connected to IoT-enabled systems, providing access to temperature data, alerts, and analytics from anywhere, facilitating process optimization and predictive maintenance.

Conclusion:

L-shaped Type K thermocouples offer a reliable and cost-effective solution for temperature measurement in salt bath furnace applications. Their versatility, durability, and ease of installation make them suitable for monitoring and controlling temperature variations within the furnace. By considering factors such as salt corrosion, temperature uniformity, and calibration, users can maximize the benefits of L-shaped thermocouples and ensure accurate and efficient operation of their salt bath furnaces.