In the world of infrared temperature sensors, there are two types of ratio pyrometers: Two-Color and Dual-Wavelength. Both use a ratio of energy measured at two wavelengths to create a temperature reading. This method of measurement allows ratio sensors to automatically compensate for emissivity variation (for ‘greybody’ materials), partially filled fields of view, and dirty windows. While both the Two-Color and Dual-Wavelength are ratio pyrometers, the design and the capabilities of each type of pyrometer are very different.

Two-Color Pyrometers

- General-purpose wavelength set

- Compensate for variable emissivity and modest optical obstruction or misalignment

- Used when there is a clear optical path between the pyrometer and target

- Measure temperatures above 1100°F / 600°C

- Ideal for scale-free and uniformly heated ferrous metals

Two-Color pyrometers use what is called a “sandwich detector” meaning that two wavelength filters are laid one on top of the other. One wavelength is a broad waveband (0.7-1.1um for example) and the other wavelength is a narrow waveband (1.0-1.1) that is a subset of the broader band. These pyrometers essentially work like a camera, taking pictures of the object that you want to measure. If you were to obstruct the lens of the camera, the picture would be distorted and inaccurate. Instead of taking a picture, the pyrometer is measuring the intensity of radiant energy from the object. However, the analogy remains the same. If you partially block the field of view, you are going to get an inaccurate reading. Some common obstructions that many manufacturers face are:

- Dirty windows and lenses

- Smoke, water, plasma, flames, or steam

- Other floating particles: dirt, dust, etc.

The good news is, two-color pyrometers are forgiving to a certain extent. However, if you are trying to measure the temperature of an object that is consistently obscured by an obstacle such as steam, you may want to consider a Dual-Wavelength pyrometer.

Dual-Wavelength Pyrometers

- Carefully selected wavelength set

- Compensate for variable emissivity, temperature gradient, severe optical obstruction, and misalignment

- Wavelength set may be selected to view through water, steam, flames, plasma, etc

- Measure temperatures above 200°F / 95°C

- Better tolerates scale, temperature gradients, and non-grey interference due to greater separation between wavelengths

Dual-Wavelength pyrometers use two separate and distinct wavelength sets on a filter wheel to measure the hottest temperature that is in their field of view. Because the design allows for separate wavelengths, these wavelength sets can be independently selected and combined to allow for some very unique capabilities. The most important capability is that you can select the wavelength sets to tolerate water, steam, flames, plasma and laser energy. This ensures a more accurate reading with the added bonus that they are more tolerant of scale, misalignment, and optical obstructions than Two-Color pyrometers. These features allow you to get a consistent and accurate reading under a wide range of operating conditions without having to make adjustments to the sensor.

The difference in design allows for two major technical benefits for the Dual-Wavelength pyrometer:

1) Dual-Wavelength pyrometers are 20x less sensitive to scale and temperature gradients

Scale is an interference to ratio pyrometers not because it is a different emissivity, but because it emits infrared energy at a different ratio. Scale is much cooler than the hot metal it sits upon and will make the pyrometer reading artificially low. The Two-Color pyrometer is designed to take an average temperature of what it sees in its field of view, whereas the Dual-Wavelength is more heavily weighted to the hottest temperature it sees.

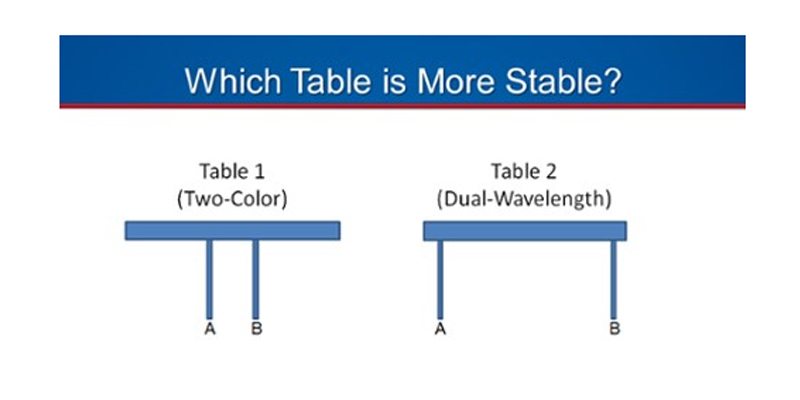

- Just like legs on a table, a ratio pyrometer is more stable when the legs (wavelengths are farther apart

- Greater separation between wavelengths make Dual-Wavelength pyrometers 20 times less sensitive to scale and temperature gradients compared to Two-Color pyrometers. An error of 40 or 60 degrees becomes an error of only 2 or 3 degrees.

2) Certain Dual-Wavelength pyrometers can view through common industrial interferences like:

Steam

Flames

Water

Plasmas

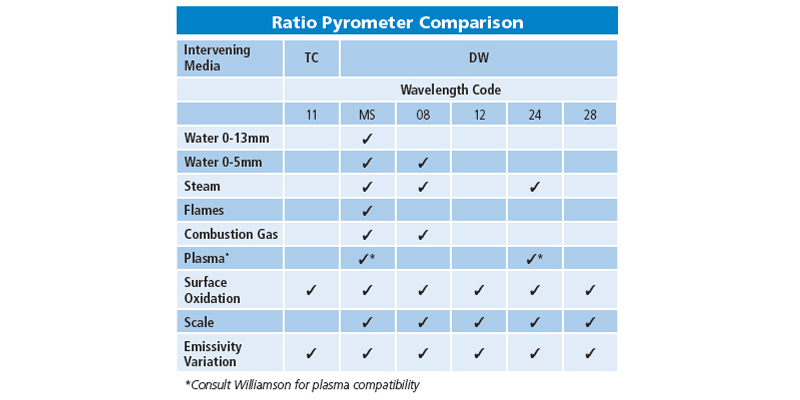

Both Two-Color and Dual-Wavelength pyrometers can compensate for emissivity variation, slight surface oxidation, and moderate misalignment. But as the chart indicates, Dual-Wavelength sensors have many more capabilities when it comes to dealing with common industrial interferences. With the ability to choose from five different wavelength combinations, the Dual-Wavelength technology allows you to select the wavelength set appropriate for your own application conditions.

For many applications, Two-Color sensors are an appropriate choice. For applications that involve any of the interferences listed above, or for applications that involve scale or temperature gradients, Dual-Wavelength pyrometers are a more appropriate choice.

In addition to the two advantages listed above, Dual-Wavelength pyrometers can also measure lower and broader temperature spans. Essentially you are locked into only one general-purpose wavelength set with the Two-Color units, but you have a greater variety of options for combinations of wavelengths with the Dual-Wavelength. As a result, the ability to select wavelengths gives the Dual-Wavelength pyrometer some significant added benefits and technical advantages over Two-Color sensors. This allows for more accurate and reliable temperature measurement in the most challenging of industrial application environments.

Wondering if a ratio pyrometer will suit your needs?

Whether you decide to choose two colors or a Dual-Wavelength pyrometer, some popular uses for them are:

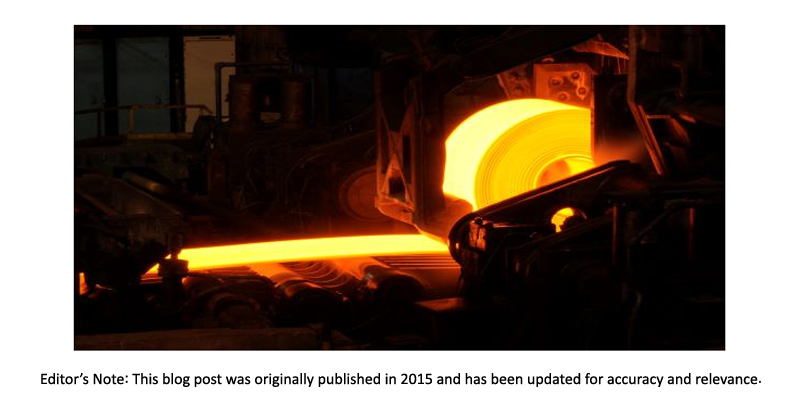

- Steel Mills

- Casting, Forming, Joining, and Heat Treating of Metals

- Induction, Resistance, Friction, Flame, and Laser Heating

- Forging Plants: Billet, Die, Heat Treat

- Wire, Rod, and Bar Mills

- Rotary Kilns, Thermal Reactors, and Solid Fuel Power Boilers

- Engineered Materials: Silicon Crystals, CVD Diamonds, Carbon Densification, High-Temperature Ceramics

Having Issues Measuring Temperatures?

No two manufacturing businesses are exactly the same, which is why we tailor our pyrometers to your specific needs. We have found that the best way to ensure accurate temperature readings is to dive into your production line. Are you measuring through heavy steam? Is there a thick piece of safety glass between your pyrometer and the material? Is the material submerged or partially blocked by water? A Dual-Wavelength pyrometer will allow you to record accurate temperatures through all of these obstacles, but knowing exactly what your needs are allows us to custom tailor our products for you.