Electromagnetic flow meters, often referred to as mag meters, are a crucial component in various industrial applications. These devices are used to measure the flow rate of conductive liquids, leveraging Faraday’s Law of Electromagnetic Induction. Here’s an overview of their use in different sectors:

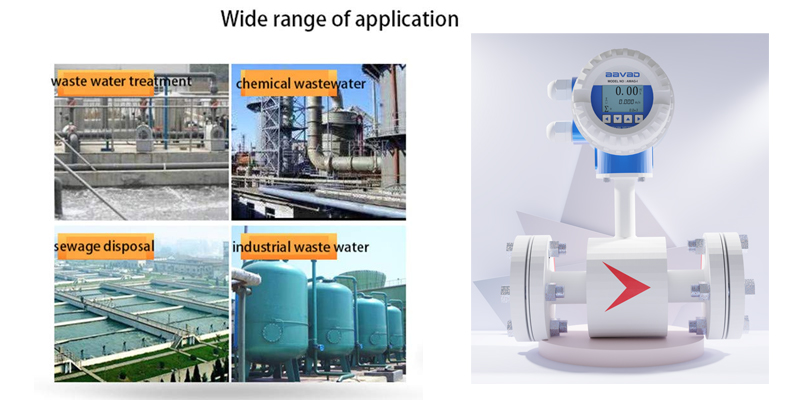

1. Water and Wastewater Management

In water treatment plants and wastewater facilities, accurate measurement of liquid flow is essential for both operational efficiency and regulatory compliance. Mag meters are commonly used because they can handle dirty water, sludge, and other particulates without clogging or loss of accuracy. They provide reliable data for process control, leakage detection, and billing purposes.

2. Chemical Industry

The chemical industry deals with a wide range of corrosive and reactive fluids. Electromagnetic flow meters are favored here due to their non-intrusive nature and compatibility with aggressive chemicals. They help in monitoring the flow rates of acids, bases, solvents, and other chemical solutions, ensuring safe and efficient processes.

3. Food and Beverage

In the food and beverage sector, maintaining hygiene and precision is paramount. Mag meters are used to measure flow rates of various liquids, including milk, juices, and syrups. Their non-invasive design ensures that there is no contamination of the product, and their accuracy helps in maintaining consistent quality and recipe adherence.

4. Pharmaceuticals

Pharmaceutical manufacturing requires precise control over fluid measurements to ensure product consistency and quality. Electromagnetic flow meters are used to measure the flow of liquid medicines, water for injection, and other pharmaceutical ingredients. Their high accuracy and ability to handle various liquid types make them ideal for this industry.

5. Pulp and Paper

The pulp and paper industry uses large volumes of water and chemical solutions in its processes. Mag meters are employed to monitor the flow of these liquids, as well as slurries, which contain both liquid and solid particles. The robust design of electromagnetic flow meters ensures durability and accuracy in these demanding environments.

6. Mining and Mineral Processing

In mining operations, precise measurement of slurry flow (mixture of water and solids) is crucial for efficient processing and transportation. Electromagnetic flow meters are used because they can handle abrasive materials and high solid content without significant wear and tear.

7. Power Generation

Power plants use a variety of fluids in their operations, from cooling water to boiler feedwater. Electromagnetic flow meters help in monitoring and controlling the flow of these liquids, ensuring the plant operates efficiently and safely. They are particularly useful in measuring the flow of demineralized water, which has low conductivity.

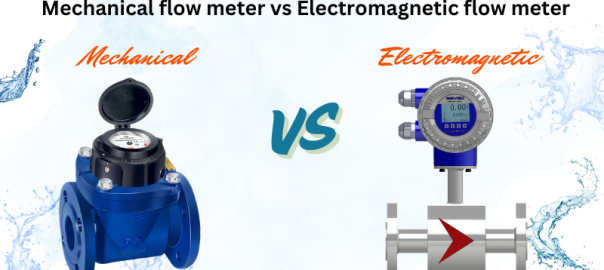

Advantages of Electromagnetic Flow Meters

- Non-Invasive Measurement: Mag meters do not have moving parts or obstructions in the flow path, reducing maintenance and the risk of pressure drop or clogging.

- High Accuracy and Reliability: They provide precise flow measurements, which are critical for process control and quality assurance.

- Versatility: Suitable for a wide range of liquids, including slurries and corrosive substances.

- Minimal Maintenance: Due to the lack of moving parts and their robust design, mag meters require less frequent maintenance compared to other types of flow meters.

Conclusion

Electromagnetic flow meters are indispensable in various industrial applications due to their accuracy, durability, and versatility. From water management to complex chemical processes, these devices ensure that operations run smoothly, efficiently, and safely. As industries continue to evolve, the role of mag meters will remain pivotal in achieving optimal fluid management and control.