“If you can’t measure it, you can’t improve it,” is a truth. Quality, safety, efficiency, and general development are all built on measurement. The majority of calibration service companies and sectors rely substantially on the precision of measurement devices to raise living standards. A calibration service’s objective is to reduce measurement error and boost confidence in accurate measurements.

The accuracy of all measuring instruments deteriorates over time.

Calibration is required if your measuring instrument significantly affects the accuracy and validity of your testing technique, which is critical and crucial to the credibility of the data produced by laboratories and testing facilities. This aspect is immediately apparent in medical and legal decisions.

Types of Calibration Services

Depending on the service being performed, the type of calibration equipment utilized varies. Asian Technology provides numerous types of calibration services offered, including the following:

- Pressure Calibration

Pressure calibration service seeks to calibrate pressure-measuring devices for gas and liquid systems operating above or below atmospheric pressures, such as pressure switches, pressure transmitters, relief valves, and barometers.

- Temperature Calibration

Temperature-measuring devices such as thermocouples, RTDs, thermistors, PRTs, bi-metal thermometers, thermal cameras, and infrared meters are calibrated using this service. This calibration process is carried out in a safe and secure setting.

- Humidity Calibration

Humidity recorders, humidity probes, humidity sensors, psychrometers, and thermohygrographs are all calibrated as part of the humidity calibration service. During humidity calibration, parameters such as relative humidity and dew point are measured. It’s done in a controlled setting, just like the temperature calibration service.

- Flow Calibration

The goal of the flow calibration service is to ensure that volumetric and mass flow meters, as well as flow controllers, in gas and liquid distribution systems, are properly calibrated. Flow calibration is required on a regular basis because it controls the flow of fluids through process equipment and pipelines, which has an impact on quality and safety.

- Pipette Calibration

Pipettes, single-channeled pipettes, multiple-channeled pipettes, and electronic pipettes are all calibrated in order to dispense accurate volumes of liquid. In analytical laboratories, pipettes are commonly utilized.

Pipette calibration services are performed by weighing a liquid carefully dispensed by the pipette at a known temperature.

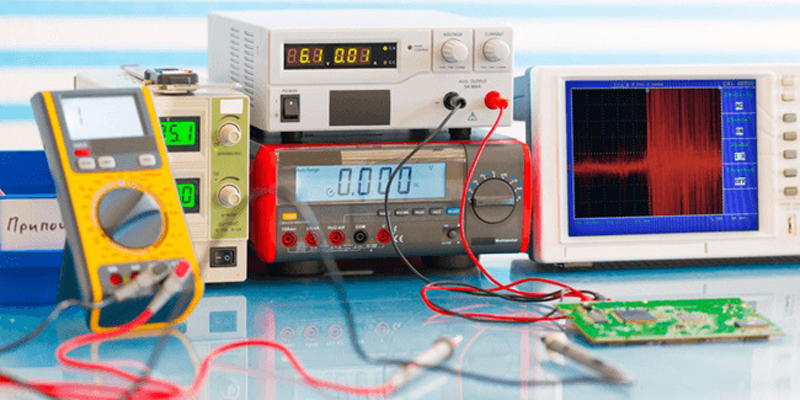

- Electrical Calibration

Electrical calibration service is performed on instruments that measure electrical properties including voltage, resistance, current, inductance, and capacitance are calibrated using electrical calibration services. This calibration service covers oscilloscopes, multimeters, data loggers, and clamp meters among other instruments.

- Dimensional Calibration

A dimensional calibration service is performed to calibrate devices that measure dimensions like length, volume, flatness, and angle. Micrometers, calipers, height gauges, and other instruments are catered to in this calibration service.

- Force Calibration

In order to calibrate measuring equipment that measures force-related characteristics including weight, torque, and compressive and tensile forces, force calibration services are provided. During measurement, adapters are used to ensure that the applied force is focused on the DUT.

Conclusion –

Finally, calibration ensures that all measurements are geographically consistent and that all measuring instruments are up to date with international agreements and standards. If parties from various regions are given with a specific measured quantity, they must agree. This is critical in international and domestic trade since the quantity of things sold equals the amount of money earned. For example, when measured in the importing country, one cubic meter of gasoline exported by a country must be exactly one cubic meter of gasoline.

A calibration service is a documented or legal service used to verify the accuracy of measuring equipment by comparing the measurement obtained by the DUT to the standard value. The deviation from the standard value is called an error.

In laboratories, testing facilities, and industrial processes, calibration is important. The geographical consistency of measurements also depends on it.